Injection molding CAE

By pre-validating problems that may occur during mold development process, it facilitates preliminary R&D process of clients.

Injection molding CAE

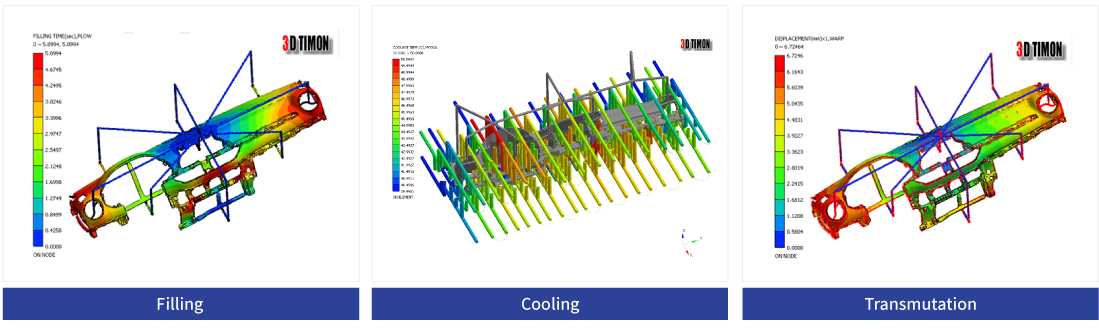

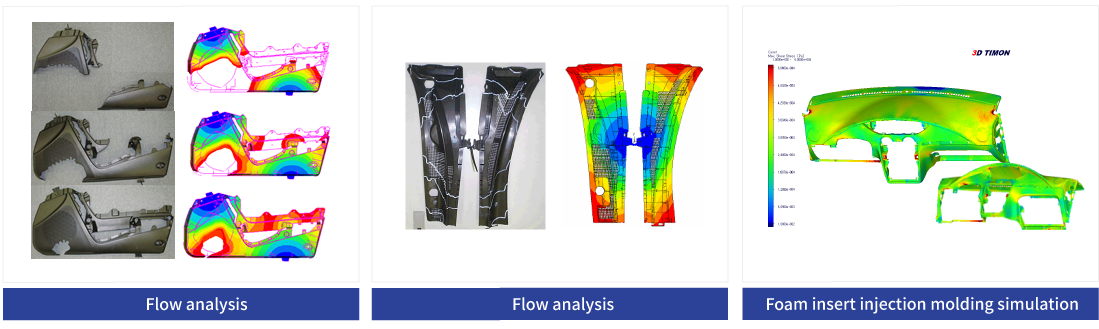

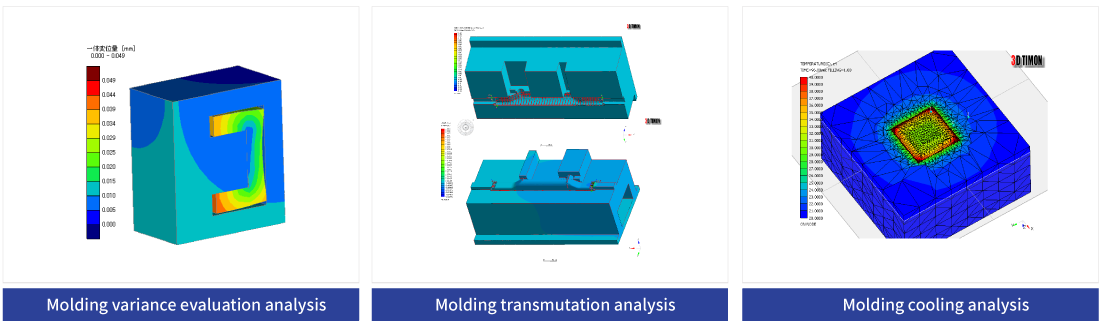

- Prevents problems through pre-validation using 3D molding simulation system (3D-TIMON)

- Performs self-development in accordance with preceding research performed by customers and their demands and verifies mass-producibility

3D Molding Simulation System (3D-TIMON)

- Select the best Gate, Runner System

- Select the best cooling system

- Decide the size of the mold taking into consideration the moldability/productivity/possibility of blow down

- Decide the optimal efficiency and size of the injection molding machine

- Injection mold the test-product/quality control

- Problem analysis and improvement

| What our clients can expect | |

| Regarding the period of delivery |

|

| Regarding productivity |

|